Tempered Glass is a specialized heat treatment process that transforms ordinary glass into a significantly stronger and safer material. At AllGlass, we utilize state-of-the-art tempering technology to enhance the structural integrity of glass, making it up to five times stronger than standard glass while maintaining perfect clarity and visual appeal.

Our tempered glass undergoes a carefully controlled heating and rapid cooling process that creates a compressed surface layer, resulting in exceptional durability and resistance to thermal stress. When broken, tempered glass shatters into small, relatively harmless pieces rather than sharp, dangerous shards, providing essential safety features for applications in residential buildings, commercial spaces, and automotive industries. With our precision equipment and expert technicians, we deliver tempered glass solutions that meet the highest international safety standards while fulfilling your specific design requirements.

Why Choose Our Tempering Service

Our Tempered Glass service stands out due to our commitment to precision and quality. We utilize the latest European technology to ensure consistent results across every glass panel. Our tempering process not only enhances safety but also improves thermal resistance, making our tempered glass ideal for energy-efficient applications. With customizable options for thickness, dimensions, edge treatments, and finishing touches, we provide tailored solutions that perfectly align with your architectural vision and functional requirements.

Superior Strength

We deliver glass that's up to five times stronger than standard glass, providing exceptional durability and resistance to impact, making it ideal for high-traffic areas and safety-critical applications.

Safety Assurance

Our tempered glass breaks into small, cubical fragments rather than sharp shards, significantly reducing the risk of injury and making it the preferred choice for doors, partitions, and areas with potential human impact.

Thermal Resistance

Our tempered glass withstands temperature differentials up to 250°C, making it perfect for applications exposed to heat sources or temperature fluctuations, including shower enclosures and kitchen backsplashes.

Precision Finishing

We ensure meticulous edge processing and surface quality in our tempering process, delivering glass with perfect optical clarity and dimensional accuracy for the most demanding architectural and design applications.

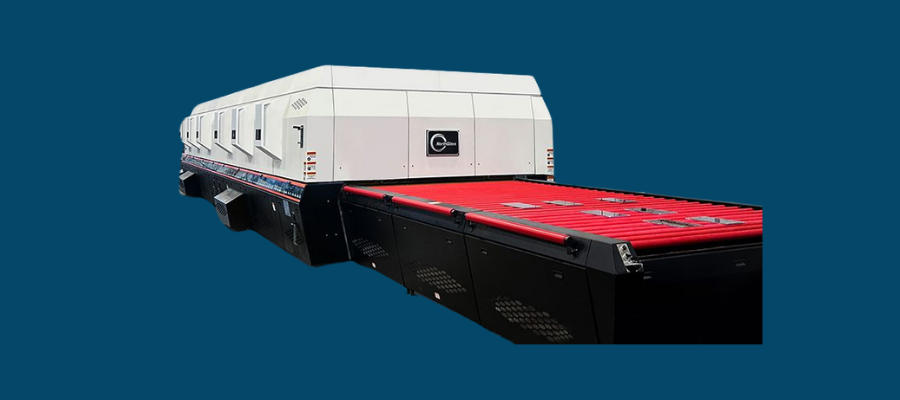

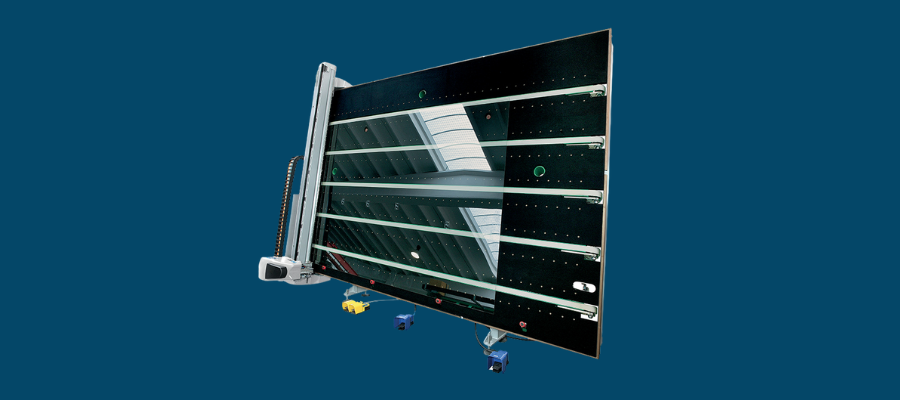

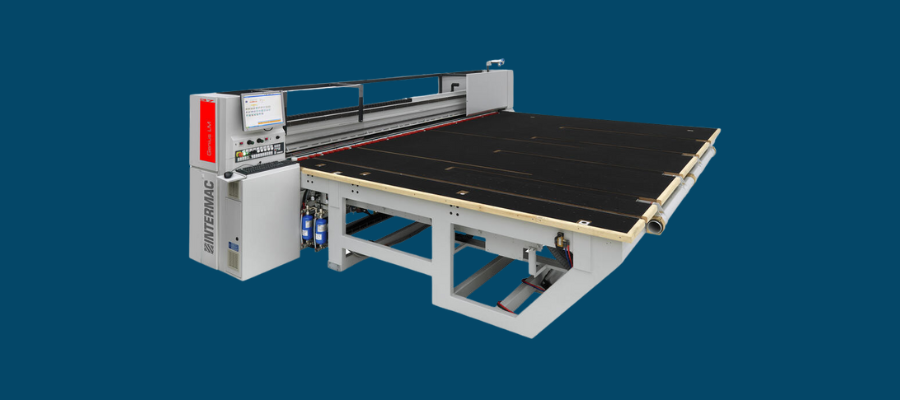

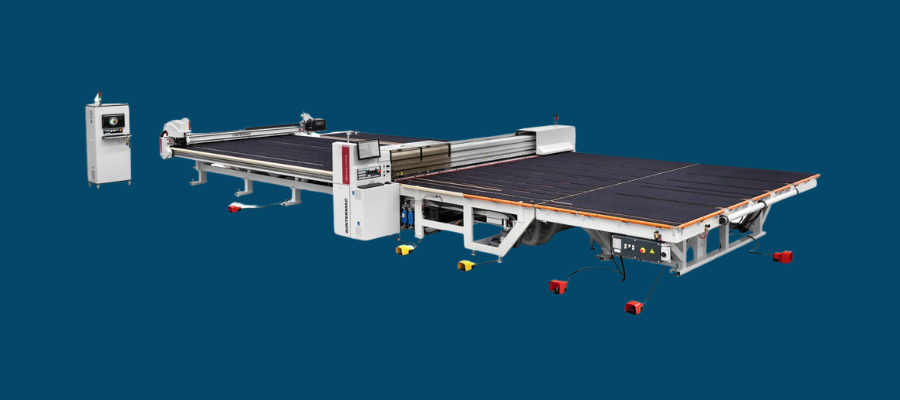

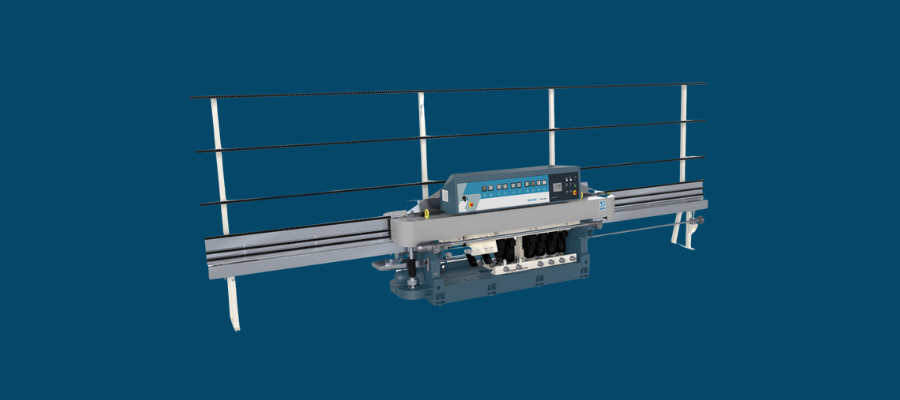

Production Machinery for Tempered Glass

Our tempered glass production relies on advanced machinery that ensures exceptional quality, strength, and safety characteristics. The cornerstone of our tempering process is the state-of-the-art North Glass tempering furnace, which precisely controls the heating and rapid cooling cycle essential for creating the compressed surface layers that give tempered glass its extraordinary strength and safety properties. Before tempering, glass sheets are precisely cut on our high-precision cutting lines—Bottero 363 evo, Intermac LM 37, and Intermac combyline—which ensure dimensional accuracy and clean edges required for successful tempering. For custom applications requiring holes, notches, or special shapes, our Bottero CNC machine performs these operations with micrometer precision prior to the tempering process. Edge processing, critical for tempering quality and safety, is performed on our advanced Bovone and Z. Bavelloni straight line edgers, which deliver perfectly finished edges free from micro-cracks that could cause failure during tempering. This integrated suite of machinery allows us to produce tempered glass with exceptional optical clarity, precise dimensions, and superior strength that meets or exceeds international safety standards while fulfilling the most demanding architectural and design requirements.

Advanced Processing

Our Tempered Glass process combines technical expertise with cutting-edge equipment to deliver superior results. Each piece undergoes meticulous inspection before and after tempering to ensure flawless quality. Our controlled heating and cooling technology creates the optimal stress pattern within the glass, maximizing strength while maintaining perfect optical properties. With precise temperature control and automated handling systems, we guarantee consistent quality across projects of any scale.

- Optical Distortion Testing

- Edge & Surface Quality Inspection

- Fragmentation Pattern Analysis

- Dimensional Accuracy Verification

- Heat Soak Testing Option

- Final Quality Certification

Benefits of Our Tempered Glass

Choosing AllGlass tempered glass solutions provides numerous advantages for your projects. Our tempered glass offers enhanced safety and security while maintaining aesthetic appeal. The increased strength allows for larger glass spans with reduced thickness, creating more open, light-filled spaces. The thermal resistance properties contribute to energy efficiency in buildings, while the durability ensures long-term performance with minimal maintenance. Additionally, our tempered glass complies with international building codes and safety standards, simplifying approval processes for your construction projects.

Frequently asked questions

Get answers to the most common questions about our Tempered Glass services. Our comprehensive FAQ section addresses technical specifications, applications, and practical considerations to help you make informed decisions about your glass requirements.

How does the tempering process affect glass appearance?

The tempering process enhances the strength of glass without altering its transparency or color. However, very slight optical distortions might occasionally be visible under specific lighting conditions due to the heating and cooling process. Our advanced technology minimizes these effects to ensure the highest optical quality.

What glass thicknesses can be tempered?

At AllGlass, we can temper glass ranging from 4mm to 19mm in thickness. Each thickness has specific applications where it performs optimally, and our experts can guide you in selecting the appropriate thickness for your project based on safety requirements, structural needs, and design considerations.

Can tempered glass be cut or drilled after the tempering process?

No, tempered glass cannot be cut, drilled, or otherwise modified after the tempering process without causing it to shatter. All cutting, drilling, edgework, and other fabrication must be completed before tempering. This is why we work closely with clients to ensure all specifications are precisely determined before beginning the tempering process.

Featured projects

-

Projects

Galeri Roma

-

Projects

Palace Hotel & SPA

-

Projects

Shkolla Servete Maçi

-

Projects

Lajthiza Invest

-

Projects

Vasco da Gama Cruiser

-

Projects

Deutsch Color Albania