Double glazing represents a fundamental advancement in window technology, utilizing two glass panes separated by a sealed air or gas-filled cavity to create a high-performance thermal and acoustic barrier. This intelligent construction dramatically improves insulation properties while maintaining excellent optical clarity and light transmission, making it the standard for energy-efficient buildings worldwide.

All Glass specializes in manufacturing premium double glazed units customized to meet specific performance requirements for diverse applications. Our state-of-the-art production facility enables precise control over every aspect of fabrication, from glass selection and spacer systems to gas filling and edge sealing. Each unit undergoes comprehensive quality testing to ensure optimal performance and long-term durability in real-world conditions.

Why Choose Our Double Glazing

Energy Conservation

Double glazed units typically reduce heat loss through windows by 50-70% compared to single glazing, dramatically improving building energy efficiency and reducing heating and cooling costs.

Comfort Enhancement

By maintaining more consistent interior glass surface temperatures, double glazing eliminates cold drafts and "cold zones" near windows, improving overall comfort throughout the space.

Acoustic Insulation

The dual-pane construction with optimized air space significantly attenuates sound transmission, creating quieter interior environments protected from traffic noise and other external disturbances.

Condensation Control

Improved thermal performance of the interior glass surface significantly reduces or eliminates condensation formation, protecting window frames and surrounding materials from moisture damage.

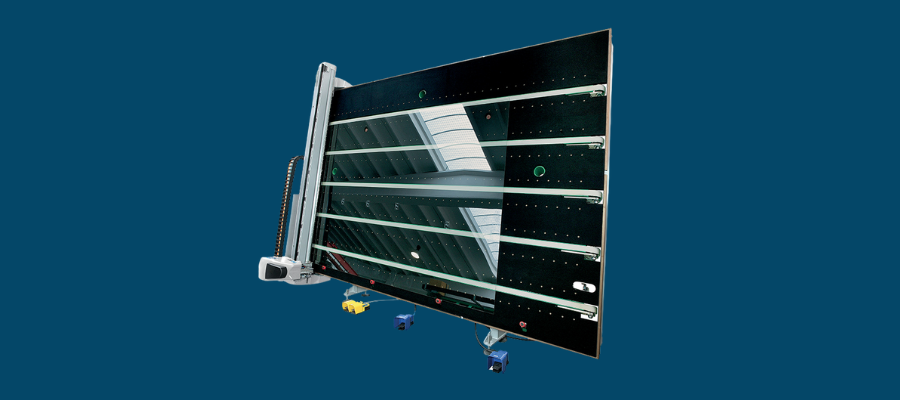

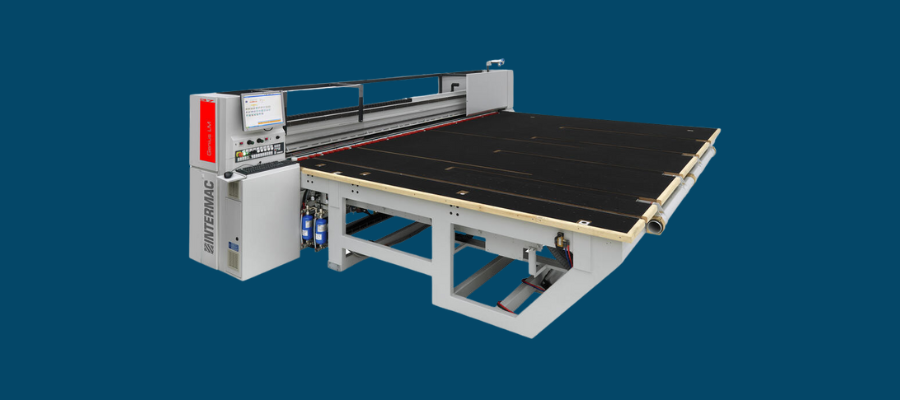

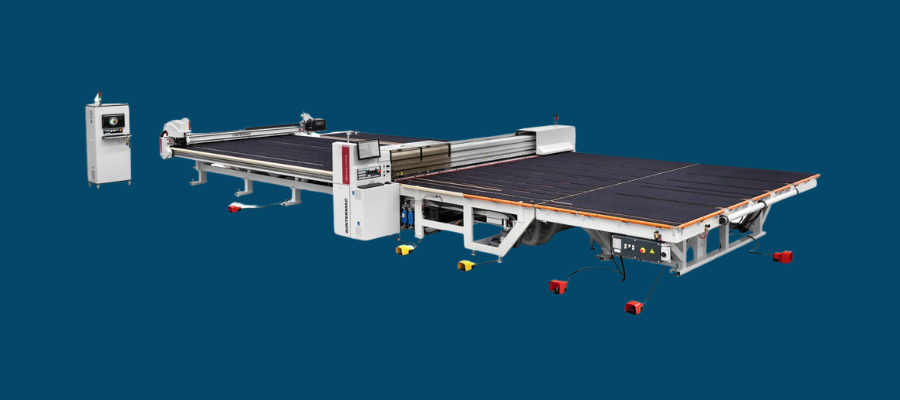

Production Machinery for Double Glazing

Our Double Glazing units are manufactured using advanced machinery that ensures exceptional quality and performance. The core of our production process features our specialized IGU assembly lines—Forel and Bystronic—which create precisely constructed insulated glass units with perfect alignment and hermetic sealing essential for long-term thermal and acoustic performance. The process begins with our precision cutting lines—Bottero 363 evo, Intermac LM 37, and Intermac combyline—which dimension glass sheets with exacting accuracy to ensure perfect fit within the completed units. These sophisticated machines work together to produce double glazing with precise spacer application, controlled gas filling, and superior edge sealing that ensures decades of reliable performance. Our integrated quality control systems verify every aspect of production, delivering double glazed units that consistently exceed industry standards for energy efficiency, sound reduction, and durability.

Planning & Strategy

- Glass Quality Inspection

- Spacer Alignment Precision

- Desiccant Verification

- Primary and Secondary Seal Integrity

- Gas Fill Percentage Testing

- Visual Clarity Assessment

Our work benefits

Frequently asked questions

What is the difference between standard double glazing and thermal double glazing?

How does the gas fill between panes improve performance?

Can existing windows be upgraded to double glazing?

Featured projects

-

Projects

Deutsch Color Albania

-

Projects

Vasco da Gama Cruiser

-

Projects

Brilliant Hotel & SPA

-

Projects

Lake View

-

Projects

Tropikal Resort