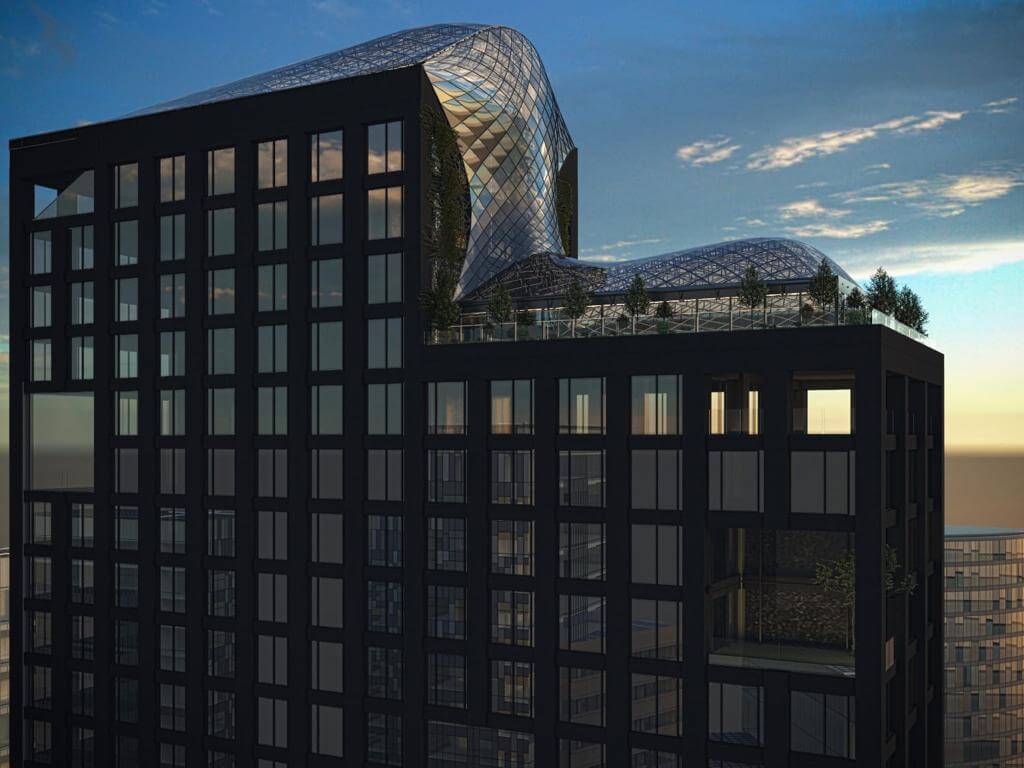

Etalbond Composite Facade Systems represent the cutting edge of architectural cladding technology, combining aluminum composite materials with advanced installation systems to create building exteriors that are both visually striking and technically superior. These façade systems offer exceptional durability, weather resistance, and design flexibility, making them ideal for modern commercial and institutional buildings seeking distinctive appearance with minimal maintenance requirements.

All Glass specializes in the design, fabrication, and installation of custom Etalbond composite façade systems tailored to each project’s specific requirements. Our comprehensive approach includes 3D modeling, structural analysis, custom panel fabrication, and precision installation. We work closely with architects and contractors to ensure seamless integration with other building systems while achieving the desired aesthetic impact and performance characteristics.

Why Choose Our Etalbond Facades

Etalbond Composite Facade Systems offer an unmatched combination of design freedom, structural performance, and long-term value. The lightweight nature of these systems reduces structural loads while their modular construction accelerates installation and minimizes on-site disruption. With numerous finish options and virtually unlimited color choices, our Etalbond facades enable architects to realize their creative vision without compromising on technical performance or budget constraints.

Material Stability

Etalbond composite panels resist warping, buckling, and oil-canning even under extreme temperature variations, maintaining a smooth, flat appearance throughout their service life.

Sustainability

Featuring 100% post-consumer recycled content for the core, 96.6% post-industrial recycled aluminum, and a manufacturing process that uses no water, Etalbond is 100% recyclable with 96.3% to 99.3% of materials returnable to the material cycle.

Core Options

Available in three different core compositions: Etalbond PE with low-density polyethylene, Etalbond FR with fire-retardant core, and Etalbond A2 with incombustible core for the most demanding applications.

Design Flexibility

Panels can be fabricated in complex shapes, curves, and perforations, with consistent color and finish quality across the entire façade regardless of complexity.

Production Machinery for Etalbond Composite Facade Systems

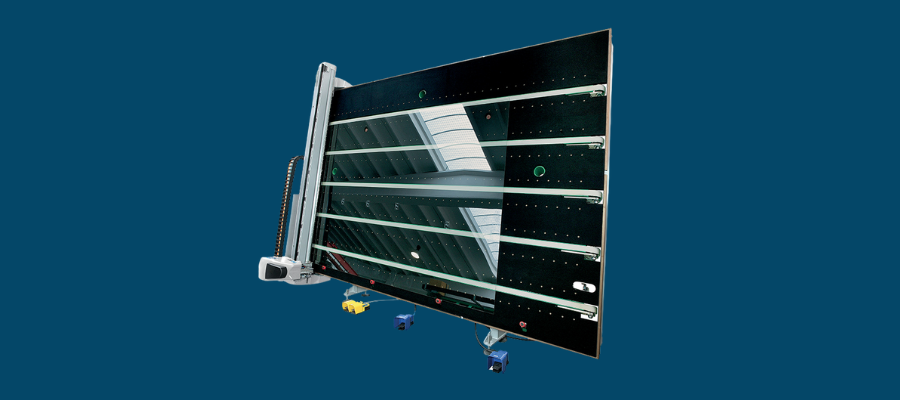

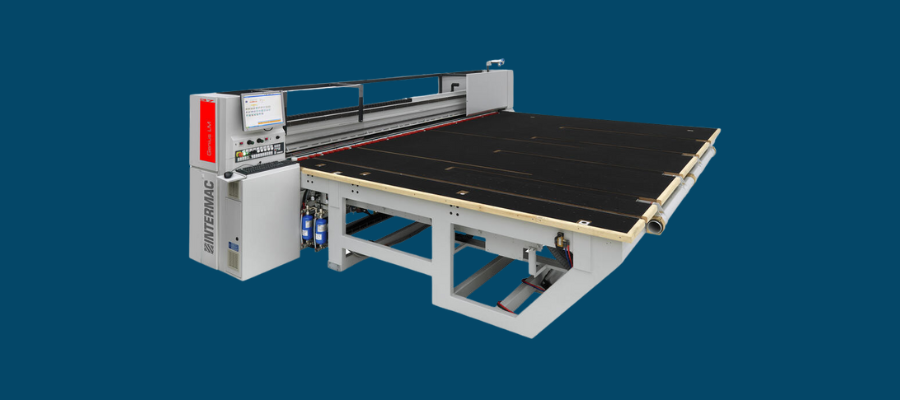

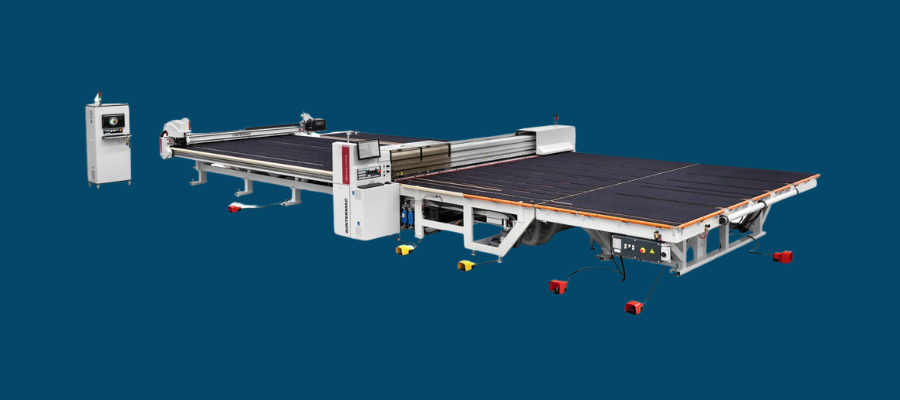

Our Etalbond Composite Facade Systems are fabricated using precision machinery that ensures exceptional quality and dimensional accuracy. The cornerstone of our production process is our advanced Bottero CNC machine, which performs critical operations including precise cutting, routing, and milling of Etalbond panels to create complex shapes, custom dimensions, and intricate details. This sophisticated equipment allows us to achieve tight tolerances and perfect edge finishes essential for professional facade installations. Our cutting lines—Bottero 363 evo, Intermac LM 37, and Intermac Combyline—provide additional cutting capabilities for straight-line processing of panels and supplementary glass components that may be integrated into facade systems. The combination of these advanced machines enables us to transform standard Etalbond sheets into custom architectural elements with exceptional precision and consistency. Whether creating simple rectangular panels or complex three-dimensional forms, our machinery delivers the exacting standards required for contemporary facade systems that maintain their visual appeal and structural integrity throughout decades of environmental exposure.

Planning & Strategy

- Material Certification

- Panel Flatness & Dimensional Accuracy

- Color & Finish Consistency

- Structural Connection Integrity

- Weatherproofing System Verification

- Installation Alignment & Tolerances

Our work benefits

Frequently asked questions

Understanding the unique properties and applications of Etalbond Composite Facade Systems helps clients make informed decisions. Here are answers to common questions about our façade systems.

What makes Etalbond composite panels different from other cladding materials?

What applications are suitable for Etalbond Composite Facade Systems?

What maintenance do Etalbond Composite Facade Systems require?

One of the major advantages of Etalbond Composite Facade Systems is their minimal maintenance requirements. The factory-applied high-quality coating systems are highly resistant to fading, chalking, and environmental soiling. Typically, only periodic cleaning with mild soap and water is needed to maintain appearance. The absence of sealants in most modern installation systems eliminates the need for regular caulk replacement. With proper installation, these facades can maintain their appearance and performance for 30+ years with minimal intervention.

Featured projects

-

Projects

MV Arcadia Cruiser

-

Projects

Courtyard Prishtina

-

Projects

Fafa Resort

-

Projects

Piramida Tiranë

-

Projects

Lake View

-

Projects

Ilad Residence