Why Choose Our Laminated Glass

Safety Enhancement

Laminated glass remains intact when broken, dramatically reducing the risk of injury from sharp fragments and providing continued protection even after impact damage.

UV Protection

Our laminated glass blocks up to 99% of harmful ultraviolet radiation, protecting interior furnishings from fading while still allowing natural light transmission.

Sound Insulation

Specialized acoustic interlayers significantly reduce sound transmission, creating quieter interior environments in noisy locations or providing privacy for sensitive conversations.

Design Versatility

Colored, printed, or textured interlayers enable creative design expressions while maintaining the functional benefits of laminated construction.

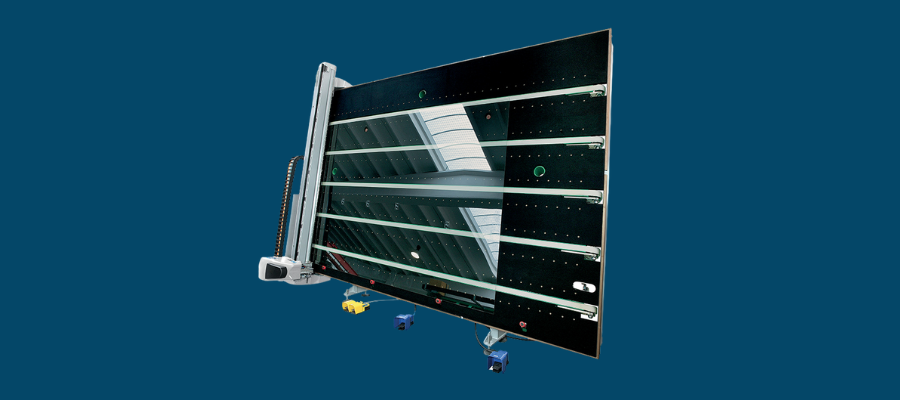

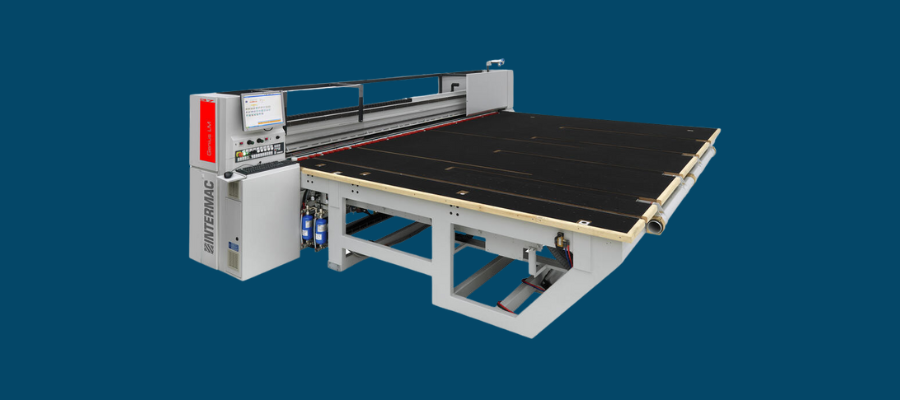

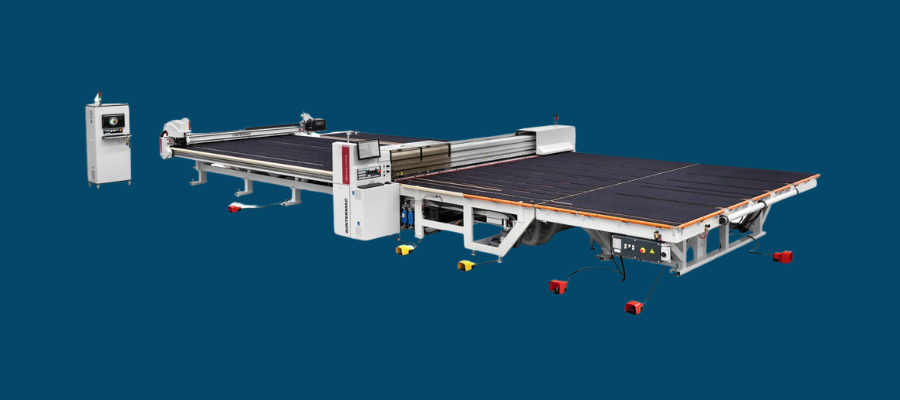

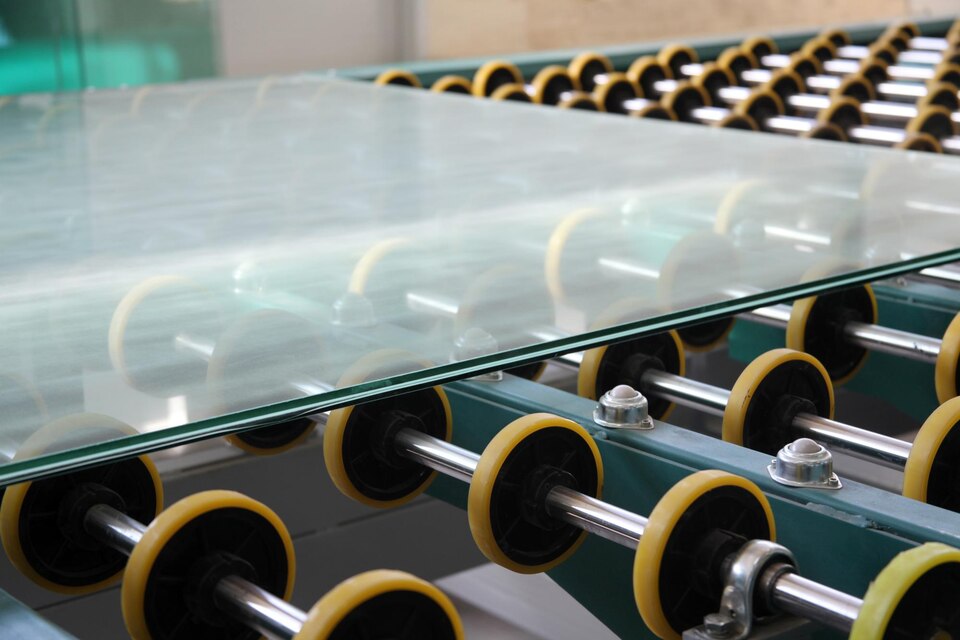

Production Machinery for Laminated Glass

Our laminated glass production relies on specialized equipment designed to deliver precision, consistency, and exceptional quality across all applications. At the core of our manufacturing process is our advanced RCN laminated furnace, which provides the precise temperature control and pressure essential for perfect bonding between glass layers and interlayer materials. The lamination process begins with our cutting-edge cutting lines—Bottero 363 evo, Intermac LM 37, and Intermac combyline—which deliver precisely dimensioned glass sheets with superior edge quality critical for successful lamination. For custom laminated applications requiring special shapes or features, our Bottero CNC machine enables intricate processing prior to lamination. This comprehensive machinery suite allows us to produce laminated glass with outstanding optical clarity, structural integrity, and performance characteristics—from basic safety glass to specialized acoustic, decorative, and security applications. Each piece undergoes rigorous quality control throughout the production process, ensuring our laminated glass meets the highest standards for safety, durability, and aesthetic appeal.

Planning & Strategy

Our approach to laminated glass projects begins with a detailed assessment of performance requirements and application conditions. We consider factors such as safety codes, security needs, acoustic targets, and environmental exposures to recommend the optimal glass composition and interlayer specification. This consultative process ensures that the final product precisely meets both technical requirements and design intentions.

- Interlayer Adhesion Strength

- Optical Clarity Verification

- Edge Sealing Integrity

- Impact Resistance Testing

- UV Transmission Measurement

- Thickness Uniformity

Our work benefits

Frequently asked questions

What safety standards does your laminated glass meet?

Can laminated glass be combined with other glass types?

How does laminated glass compare to tempered glass for safety applications?

Featured projects

-

Projects

Secret Garden Residence

-

Projects

Cunard’s Queen Mary 2

-

Projects

Royal G Hotel & Spa

-

Projects

Fafa Resort

-

Projects

Valbona Resort & SPA

-

Projects

Albaelettrica shpk